Forming Technology Forum 2018

Conference: July 2 & 3, 2018

Zurich, Switzerland

Download Download Proceedings 2018 (PDF, 9.5 MB)

Experimental and numerical methods in the FEM based crack prediction

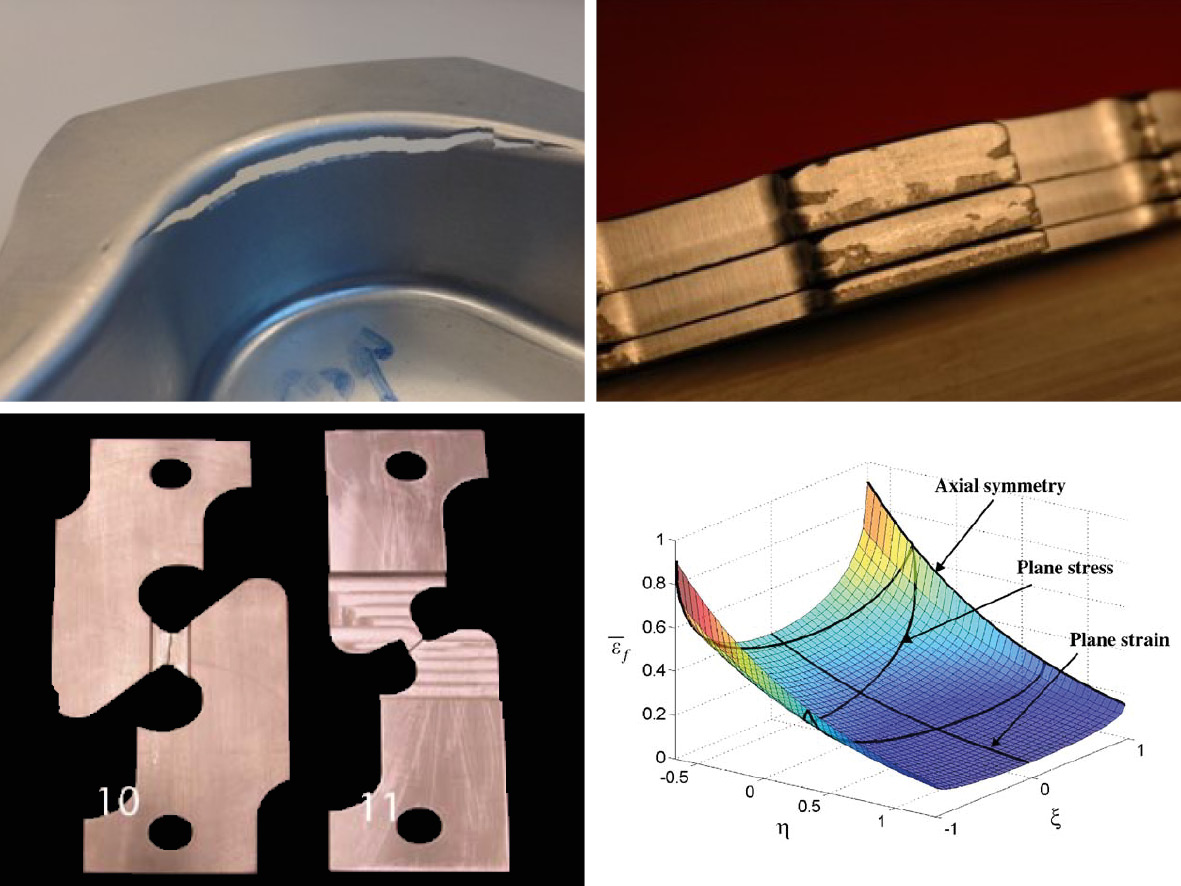

Strain localization, which precedes fracture, is used as limiting formability factor for many forming processes. In some cases, however, process constraints or material properties may prevent localization and directly deform up to the fracture limits. As far as sheet metal forming is considered such situations are bending cracks, edge cracks and the so-called shear fracture phenomenon. In the current state of the art, a universally accepted fracture criterion or, to make an analogy to the FLC a Crack Limit Curve (CLC) is still lacking. A number of experimental setups have been proposed to measure fracture strains but none of these received the acceptance enjoyed by Nakajima tests. Furthermore the correct treatment of the problem in FEM including mesh dependence and crack propagation is also still unsolved.

An even more complex situation is observed in the fracture modeling of bulk metal forming processes. The recent literature discusses a large number of coupled and uncoupled damage evolution laws which aim capturing the gradual degradation of the material before fracture. These however mostly stay at a theoretical level, lacking direct measurements and are often characterized inversely to deliver the observed macroscopic behavior. A more widely used approach is the identification fracture strains in function of stress triaxiality as proposed by Johnson and Cook. This in combination to damage evolution approaches is better able of modelling the experimental outcomes. In addition to the stress triaxiality an increasing number of approaches nowadays also include the effect of the Lode parameter. Although the theoretical foundations of this choice are well understood, it is often challenging to create reliable experiments, especially in the low triaxiality regimes.

The goal of the conferences is to discuss the current state of the art in the «crack prediction and modeling field» and to explore new ideas for better numerical approaches. An important contribution should be the proposal of better standardized experimental methods which are applicable to industrial circumstances.